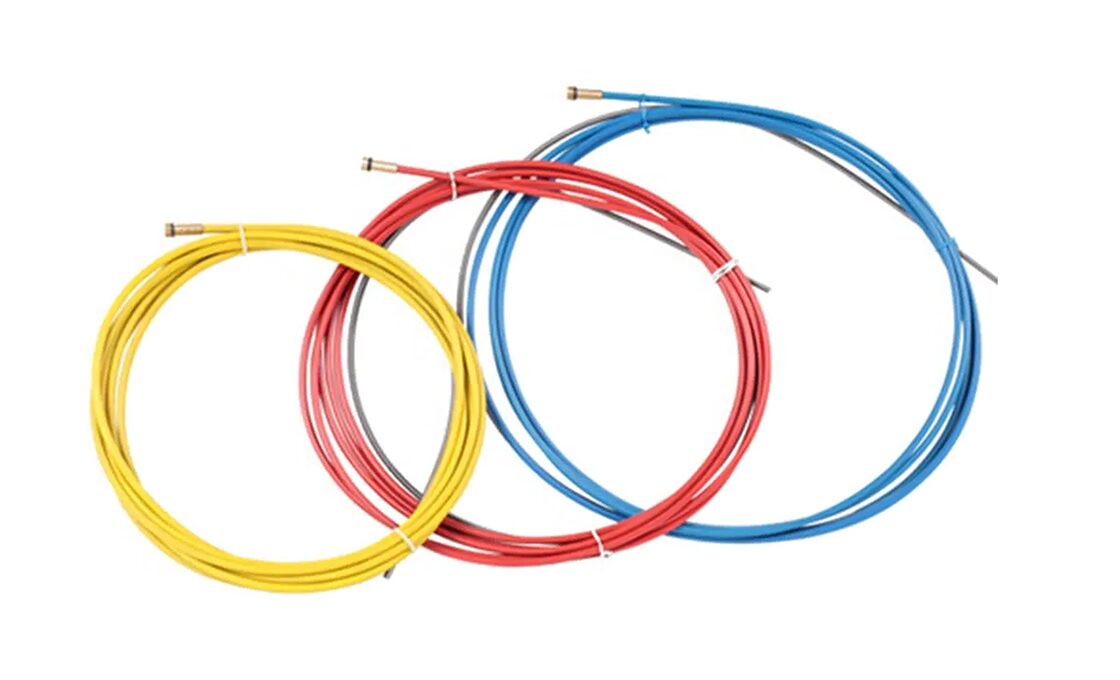

MIG contact tips are consumable components that provide electrical contact for welding wire as it feeds into the weld pool. They’re compatible with welding guns, spool guns, and push-pull systems from manufacturers including Bernard, Tweco, Miller, Lincoln, and Hobart, as well as Spoolmate and SpoolRunner series equipment.

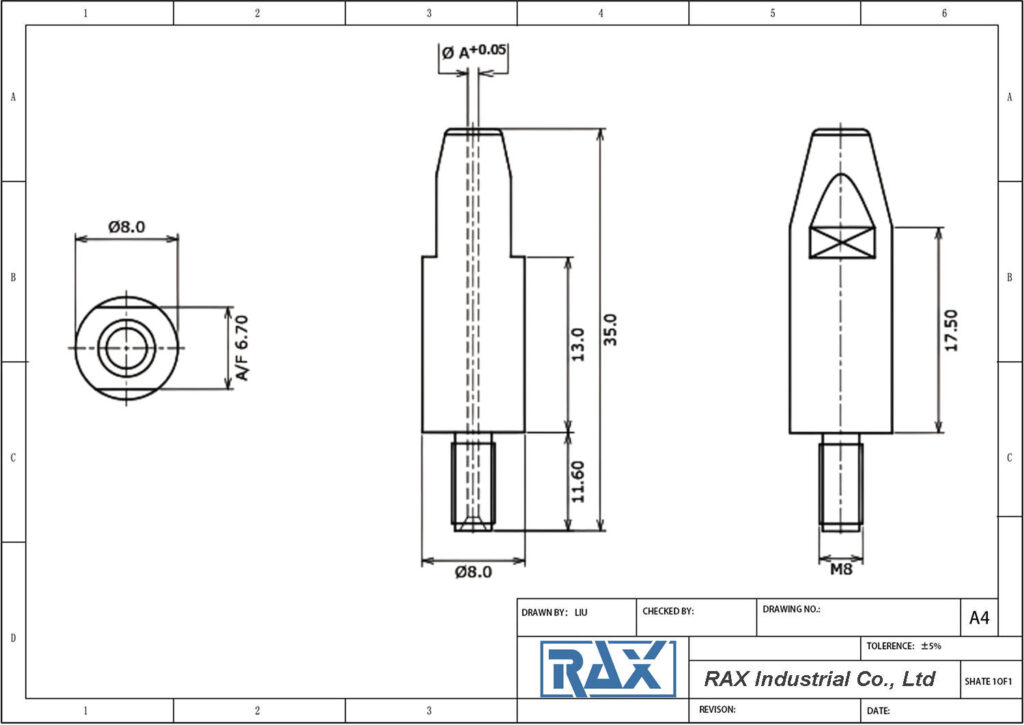

Premium copper or copper alloy construction delivers effective electrical conductivity for consistent arc stability. Precision-machined internal diameters promote smooth wire feeding for solid, flux-cored, steel, stainless steel, and aluminum wires. Select designs feature tapered bases for improved conductivity or recessed configurations that reduce heat exposure and enhance cooling from shielding gas.

Available in standard, heavy duty, and tapered styles across multiple wire diameter sizes—including 0.023, 0.030, 0.035, 0.040, 0.045, 0.052, and 0.062 inches—these tips are commonly supplied in multipacks of 5, 10, or 25 units. This provides cost-effective replacement solutions for fabrication, automotive, and industrial Metal Inert Gas (MIG) welding environments where consistent performance and reliability are essential.

Enhance Your Welding with RAX Industrial Contact Tips

MIG welding is a versatile process preferred for joining metals in all positions. RAX Industrial is a leading integrated manufacturer of welding equipment and consumables. With over 20 years of dedicated expertise, our foundation as an independent domestic manufacturer is built on precision engineering and a commitment to innovation. This focus directly informs the design and production of our MIG contact tips, which are manufactured in our 18,000 m² facility.

We are dedicated to providing innovative and dependable products that meet the highest industry standards. This philosophy ensures our MIG contact tips are precision-engineered from top-grade materials to ensure a reliable and stable connection, enhancing welding performance and providing long-lasting durability for efficient operations. Our substantial capacity, producing over 11 million contact tips annually, is backed by a specialized R&D team, guaranteeing a top-quality product built to withstand rigorous use.

Trust in our high-quality products to deliver exceptional results. Contact us below and someone will reach out to you.

| Parameter | Specification |

|---|---|

| Style / Configuration | Standard, Heavy Duty, Tapered |

| Wire Diameter (in.) | 0.023″, 0.030″, 0.035″, 0.040″, 0.045″, 0.052″, 0.062″ |

| Wire Diameter (mm) | 0.6 mm, 0.8 mm, 0.9 mm, 1.0 mm, 1.2 mm, 1.3 mm, 1.6 mm |

| Compatible Wire Types | Solid wire, Flux-cored wire; Steel, Stainless Steel, Aluminum |

| Primary Material | Copper / Copper Alloy |

| Compatible Equipment | MIG guns, spool guns (e.g., Spoolmate, SpoolRunner), and push-pull systems from various manufacturers (e.g., Bernard, Tweco, Miller, Lincoln, Hobart). |

| Key Feature | Precision-machined internal diameter for consistent wire feeding and arc stability. |

| Typical Packaging | Multipacks (e.g., 5, 10, or 25 units). |

Frequently Asked Questions

What is the primary function of a MIG contact tip?

The contact tip serves two essential functions: it guides the welding wire to the weld pool and transfers the electrical welding current to the wire as it passes through the tip's bore. This dual role is critical for maintaining a stable arc and consistent wire feed during the welding operation.

What materials are used and how do they impact performance?

Contact tips are precision-machined from premium copper or copper alloy. Material selection directly determines tip longevity, electrical performance, and thermal stability:

How do I select the correct tip size and type for my application?

The inner diameter (ID) should match your welding wire diameter, with adjustments based on wire characteristics and process requirements:

Which MIG guns are these contact tips compatible with?

Our tips are precision-engineered for compatibility with Bernard® MDX, BTB, TGX, T-Gun, Clean Air, and IronPro™ Series guns, as well as Tregaskiss, Miller Spoolmate, Hobart spoolguns, Tweco® models (No. 1 and Spray Master®), all M-Series MIG guns, 1200 Amp Twin-Wire Torches, and Binzel, Lincoln, Esab, and Panasonic systems.

How do I install the contact tip?

Standard contact tips thread into the diffuser of your MIG gun. For certain models, we offer features like the Bernard® Quik Tip™ design, which allows the tip to install securely with just one quick twist for easier maintenance and replacement.