MIG Gun Consumables Kits provide essential replacement parts for standard MIG welding torches, ensuring consistent operation by replacing worn components. We offer a comprehensive range of kit configurations to support various wire sizes, from 0.6mm (.023″) to 1.2mm (.045″), tailored for everyday repair and general fabrication tasks.

Our strength lies in broad compatibility across multiple equipment platforms. Rather than a one-size-fits-all approach, we provide specific kits designed to match different brands and international torch standards, including Euro-style and other common architectures. For unique requirements, we offer customization options to ensure the components precisely fit your specific gun models and production needs.

A typical kit includes standard copper contact tips, durable gas nozzles, and brass or ceramic gas diffusers. These parts are organized in a practical, compartmentalized plastic box for easy identification. By providing a wide selection of models and custom-tailored sets, we help workshops manage inventory for diverse equipment fleets with reliable, standard-grade parts.

Choosing the correct kit model ensures a proper fit and minimizes downtime. Our economical solutions offer a cost-effective alternative to sourcing individual parts, providing a steady supply of essential consumables for high-volume use without excessive costs.

RAX Industrial: Premier Manufacturer of MIG Gun Consumables Kits

RAX Industrial manufactures and offers MIG welding parts, torches, and guns that are built with the welder in mind. With over 20 years of experience as an integrated R&D and manufacturing hub, we offer cutting-edge products that push the limits of durability and efficiency in the welding industry.

This expertise is embodied in our MIG Gun Consumables Kit. We ensure every kit meets rigid standards through advanced manufacturing at our 18,000 m² facility, including spectroscopic verification of raw materials and micro vision-inspection of all critical dimensions. This commitment results in consumables designed for simplicity and built for durability, helping to minimize downtime and inventory costs.

From general fabrication to automotive manufacturing, our consumables are engineered for your application. As a partner focused on innovation and OEM/ODM support, the RAX Industrial team can help configure the perfect consumable solution for your needs.

| Category | Details | Specifications |

|---|---|---|

| Compatibility | Multi-Brand Support | Kits available for various major brand standards and Euro-style torches. |

| Customization | Tailored Configurations | Custom component selection and quantities based on client requirements. |

| Contact Tips | Standard Materials | E-Cu Copper (Standard grade) |

| Gas Nozzles | Common Styles | Copper or Brass (Cylindrical / Conical) |

| Diffusers/Adapters | Standard Fittings | Brass or Ceramic (Model-specific fit) |

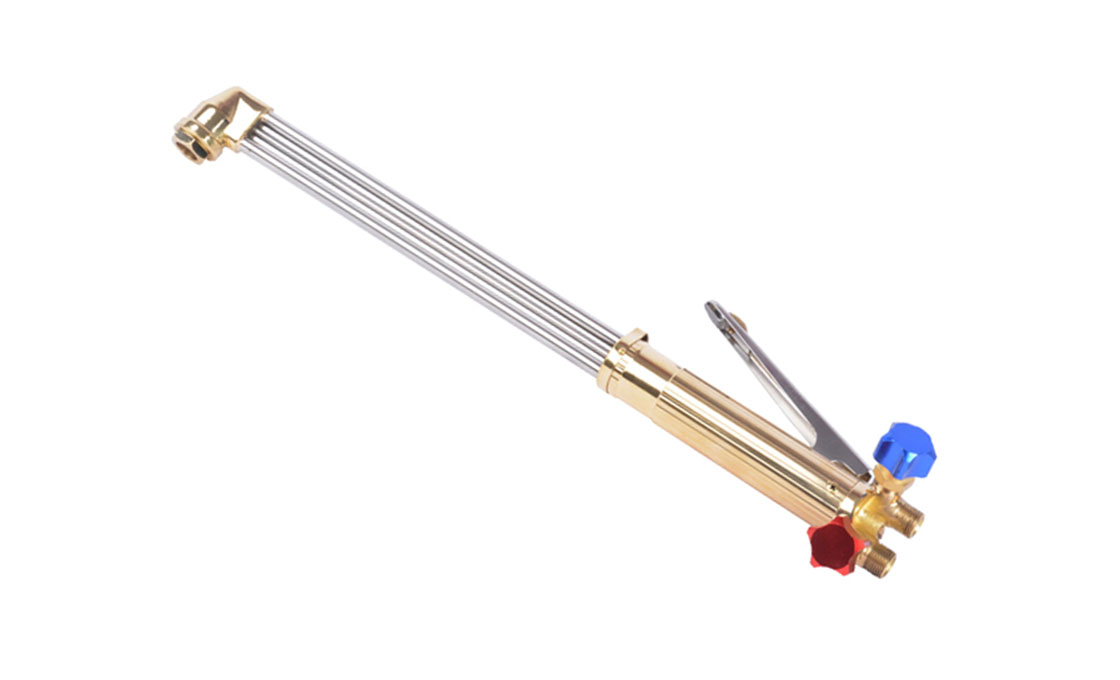

Plasma Cutting Torch

Gas Cutting Torch

Robot Welding Torch

Frequently Asked Questions

What is included in a MIG gun consumables kit?

A MIG gun consumables kit typically includes the high-wear parts around the torch front end, such as contact tips, gas nozzles, and a diffuser or tip adapter, and in some cases additional items like insulators or spare O-rings. These kits group the essential components needed to restore proper wire feeding, electrical contact, and shielding gas coverage on compatible MIG guns.

Why should I use a dedicated MIG gun consumables kit instead of buying parts individually?

A dedicated kit makes it easier to keep matching parts on hand for a specific gun series and wire size, reducing compatibility errors and downtime when consumables wear out. Pre-selected kits also help maintain consistent weld quality by ensuring that the tip, nozzle, and diffuser are correctly paired for the gun type and process.

How do I choose the right MIG gun consumables kit for my torch?

To select the correct kit, match it to your MIG gun model or series and the wire diameter you use most often, for example 0.8 mm, 0.9 mm, or 1.0 mm wire. Always check the gun’s spares or parts list so that the tip style, diffuser type, and nozzle configuration in the kit correspond to your existing torch.

Are consumables kits interchangeable between different MIG gun brands or styles?

Most kits are designed around a specific gun family or consumable style, so they are not universally interchangeable between all brands. Even where two guns look similar, differences in tip threads, diffuser design, and nozzle dimensions often mean that only kits matched to your gun series will fit correctly.

How often should I replace the consumables in my MIG gun kit?

Replacement frequency depends on amperage, duty cycle, material type, and shielding gas, but contact tips and nozzles are usually treated as routine wear parts. Inspect the tip bore, gas ports, and nozzle face regularly, and replace components when you see burn-back, unstable arc starts, or excessive spatter buildup affecting gas coverage.

Can one consumables kit support multiple wire sizes or processes?

Many kits are optimized around a single wire diameter, but some include mixed tip sizes or can be used with different solid or flux-cored wires as long as the tip bore and process range are suitable. For best results, match the tip size closely to the wire diameter and use nozzles and diffusers that are rated for your typical amperage and shielding gas.

What are good practices for storing and using MIG gun consumables kits?

Store kits in a dry, clean area to prevent corrosion on contact surfaces and keep parts organized in their case or compartments. When installing items from the kit, follow the sequence recommended for your gun, avoid overtightening threads, and ensure tips, diffusers, and nozzles are free of debris before welding.

How can a consumables kit help improve productivity and reduce welding downtime?

Keeping a dedicated kit next to each machine allows operators to change worn contact tips, nozzles, and diffusers immediately instead of waiting for individual spares. This reduces unplanned stoppages, supports more consistent weld quality, and can lower overall consumable cost by minimizing trial-and-error with mismatched parts.