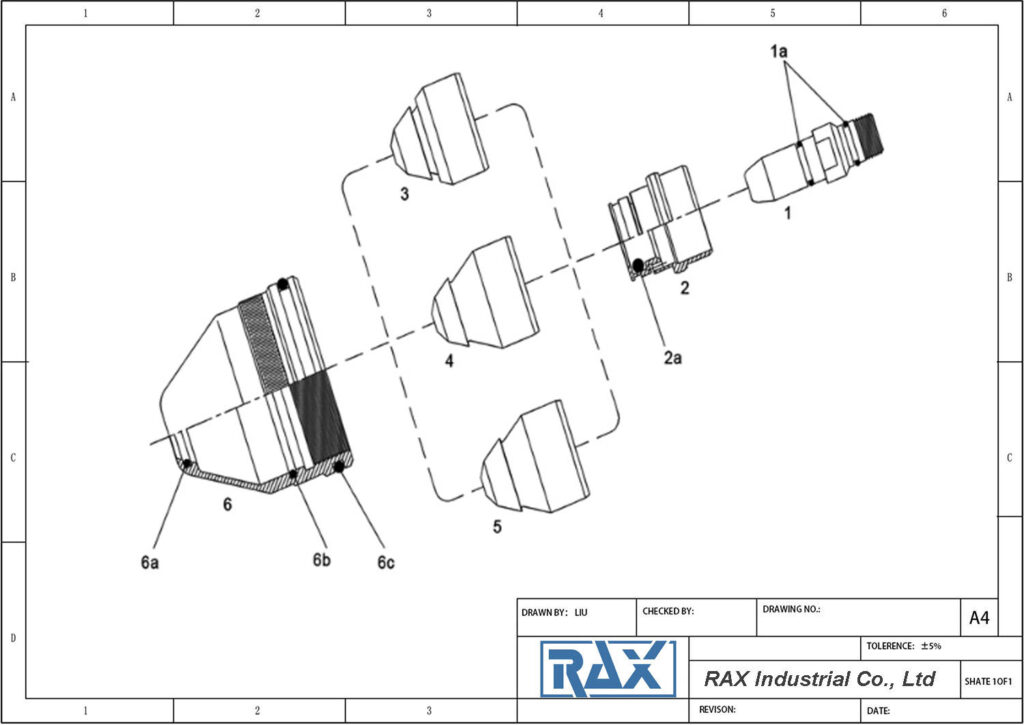

A plasma electrode is a critical consumable that serves as the primary electrical contact point for arc initiation and maintenance in GTAW cutting systems. Our electrodes are precision-engineered featuring high-purity hafnium inserts embedded within premium copper-alloy bodies. This material composition ensures efficient electron emission and superior thermal conductivity, allowing for rapid arc starting and exceptional stability even during continuous, high-amperage industrial operations.

Manufactured using advanced CNC milling processes, these electrodes achieve strict dimensional concentricity and optimized surface finishes. This precision manufacturing directly enhances arc alignment and minimizes heat-affected zones, resulting in cleaner cuts and significantly extended component lifespan. Our production line ensures universal compatibility across industry-standard platforms, including the SL-series architectures, high-definition industrial systems, and universal PT or iPT torch designs ranging from 40A to heavy-duty 105A configurations.

Designed for high-volume B2B supply, our electrodes provide a reliable, cost-effective solution for diverse metalworking environments. They deliver consistent performance when cutting conductive materials such as carbon steel, stainless steel, and aluminum, helping fabrication shops reduce maintenance downtime and maintain peak operational efficiency across varied torch fleets.

RAX Industrial: A Leading Plasma Electrode Manufacturer

At RAX Industrial, we are dedicated to delivering superior quality and providing ideal support to both domestic and international buyers for our Plasma Electrodes. We uphold a win-win philosophy, striving to build long-term cooperative partnerships with clients worldwide. Our growth is intrinsically linked to our customers’ achievements.

With over 20 years of manufacturing expertise housed in a modern 18,000 m² facility, our integrated R&D hub—powered by a team of more than 50 specialists—ensures every electrode is scientifically engineered from pure raw materials. We spare no expense in acquiring the most advanced equipment and implementing automated production lines. This commitment guarantees years of trouble-free service and has attracted a loyal customer base from over 40 countries.

Our Plasma Electrodes are precision-engineered for compatibility with leading torch brands, available in improved designs and a rich assortment to meet diverse needs. We supply our products across the globe.

Technical details include compatibility with various plasma torch models and amperage ratings, such as electrodes for 80A rated systems. Our consumables are part of an impressive annual output exceeding 270,000 torch sets and 11,000,000+ components, all backed by ISO 9001:2015 certification.

| Parameter Category | Technical Parameter | Industrial Specification / Value |

|---|---|---|

| Basic Information | Product Type | High-Performance Plasma Cutting Electrode |

| Primary Function | Serves as the primary electrical emission point; provides arc initiation and maintenance for consistent plasma cutting. | |

| Technical Scope | Platform Compatibility | Universal fit for SL-series, PT/iPT-series, HPR/HD architectures, and major global industrial torch platforms. |

| Operating Current Range | 40A – 105A (Covers standard, high-definition, and heavy-duty configurations). | |

| Applicable Materials | Carbon Steel, Stainless Steel, Aluminum, and specialized Alloys. | |

| Material & Craft | Emission Insert Material | High-Purity Hafnium (Hf) for superior arc stability and longevity. |

| Electrode Body | Premium Copper-Chromium-Zirconium (Cu-Cr-Zr) alloy; high thermal and electrical conductivity. | |

| Surface Protection | Precision Chrome-plated or high-polish finish to resist oxidation and spatter. | |

| Manufacturing | Machining Process | Multi-axis precision CNC milling ensuring ultra-tight concentricity and dimensional tolerances. |

| B2B Logistics | Supply Configuration | Industrial bulk packaging, customized wholesale sets, or OEM labeling available. |

| Quality Assurance | ISO 9001:2015 certified production; 100% inspection for dimensional integrity and alignment. |

Frequently Asked Questions

What is a plasma electrode and how does it work?

A plasma electrode is a critical consumable that initiates and maintains the cutting arc in a plasma torch. It facilitates electrical conduction through ionized gas (plasma), transferring high-energy current from the power source to the workpiece to melt and cut through conductive metals with precision.

What are the key advantages of using high-quality plasma electrodes?

- High Thermal Conductivity: Optimized copper bodies dissipate heat rapidly, preventing premature wear.

- Arc Stability: Premium emission inserts ensure a consistent, focused arc for cleaner cut edges.

- Extended Lifespan: Advanced manufacturing reduces erosion and corrosion, lowering the frequency of consumable changeovers in high-production environments.

What are the primary industrial applications for these electrodes?

These electrodes are designed for demanding metalworking sectors, including:

- Material Processing: Precision CNC cutting and manual fabrication of carbon steel, stainless steel, and aluminum.

- Heavy Industry: Shipbuilding, structural steel construction, and heavy equipment repair.

- Automotive & Manufacturing: Chassis fabrication and high-volume industrial production lines.

What types of plasma electrodes are available, and how do I select the right one?

Electrodes are primarily distinguished by their emission material and amperage rating:

- Hafnium-Tipped: The industrial standard for oxygen and air cutting, providing excellent stability and long life.

- Silver-Tipped: Features superior thermal conductivity to dissipate heat faster, often doubling the service life in high-amperage automated systems.

Selection should be based on your specific torch model (e.g., SL60, iPT60, or HPR series) and operating amperage. Always match the electrode to the corresponding nozzle and gas type for optimal performance. RAX Industrial offers both standard and extended models for specialized cutting needs.

Is the investment in premium electrodes justified?

Yes. While the initial cost may be higher, premium electrodes with high-purity hafnium or silver inserts offer significantly longer operational life and more consistent arc performance. This reduces machine downtime and maintains high cut quality, ultimately lowering the total cost per foot of cut.

Does RAX Industrial offer customization and OEM services?

We provide comprehensive OEM/ODM services, including private labeling and custom material specifications. Our agile manufacturing capabilities allow us to develop and prototype components tailored to your specific industrial application and torch configuration.

What are your quality certification and production standards?

RAX Industrial is ISO 9001:2015 certified, adhering to strict international quality standards (CE, TUV, RoHS). We utilize an advanced QC lab with OES material analysis to ensure consistent purity of our copper alloys and hafnium inserts, ensuring reliable performance in every batch.

What warranty and global shipping options are available?

We provide a 12-month manufacturing warranty on our electrode assemblies. We offer diverse international shipping solutions for B2B clients and distributors worldwide, ensuring reliable delivery for large-scale procurement and supply chain requirements.

What payment methods are accepted for B2B orders?

We accept standard commercial payment methods including Wire Transfer (T/T), Letter of Credit (L/C), and secure online corporate payments. For specific credit terms or volume pricing, please contact our sales department.

Are any manuals or technical files included with the electrodes?

Detailed technical specifications and product catalogs are available upon request. For installation guides, torch compatibility charts, or material safety data sheets, please contact our technical support team.