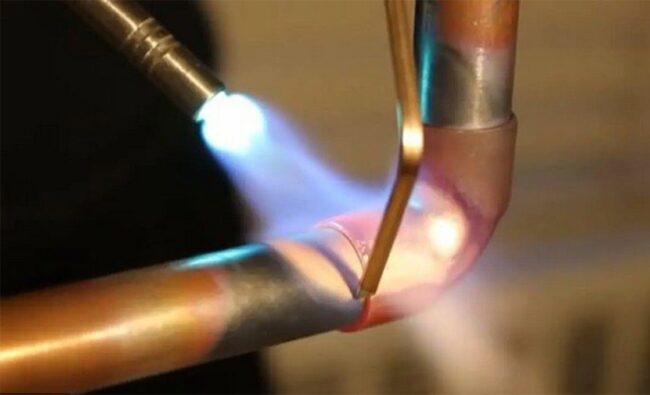

Steps for Safe Oxy-Fuel Torch Setup: Tips for Beginners

Setting up an oxy-fuel torch safely is critical for both ensuring the quality of your work and maintaining a safe work environment. The correct setup process involves inspecting equipment, following safety protocols, and properly adjusting components to avoid accidents and equipment damage. Below are the essential steps to follow for a safe and efficient oxy-fuel…